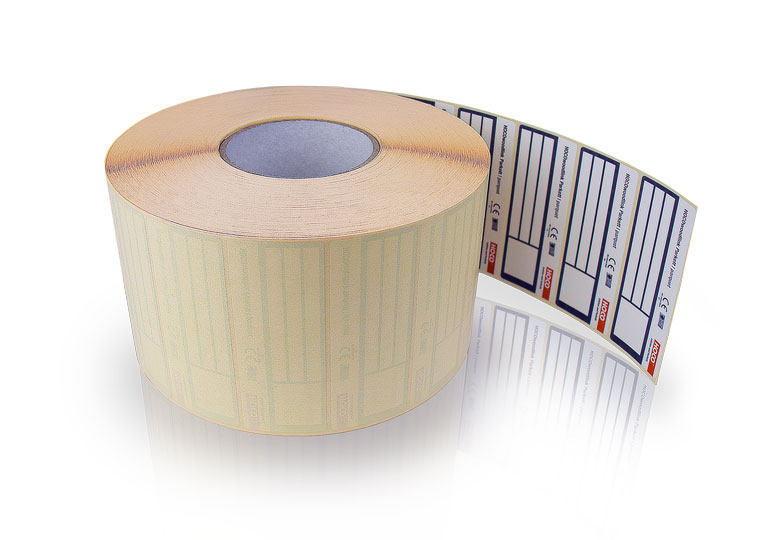

Synthetic labels

Synthetic labels are used where paper labels reach their limits or where there are special requirements in terms of appearance and properties. Depending on the type of synthetics, durability, resistance to different chemicals, UV light, heat/cold resistance and water resistance are among its strengths.

Synthetic types

| Polyester (PET) |

| Labels made of polyester are considered to be very stable and resistant, which is why they are particularly durable. In addition to good dimensional stability, they also have strong temperature resistance. Thanks to this, they can be used in a temperature range from -60° C to + 150° C without expanding or shrinking. This makes polyester labels very suitable as a base material for data and digital printing (including inkjet, laser and thermal transfer printing). A very good resistance to water, petrol, fats, oils and alcohol makes it particularly recommended for high-quality nameplates. They also withstand external weather conditions well. |

| Polyethylene (PE) |

| Polyethylene labels are the most commonly used plastic labels in today's label production. The main features include resistance to chemicals, acids and alkalis, good resistance to moisture and good printability due to the smooth surface finish. They do not contain any plasticizers, silicone or heavy metals and are completely free of chlorine, halogen and sulfur, which even gives them the label 'recyclable'. Typical areas of application are shipping and product labels, hygiene articles or even applications in the food industry. |

| Polypropylene (PP) |

| The structure of labels made of polypropylene is quite similar to that of labels made of polyethylene, but there are still clear differences in terms of properties. Particularly noteworthy is the basic resistance of the material to organic solvents and a very high chemical resistance. This makes it easy to stick even under demanding conditions. Especially in the industrial area, where regular contact with various solvents and greases is the program, PP labels impress with their qualities. With a temperature resistance of 0° C to 100° C, however, the material is also used in many other industries and fields of application, such as in the packaging and cosmetics industry as well as on advertising and household products. |

| PVC |

| PVC labels are particularly impressive due to their tear resistance and compactness. Thanks to the adaptable material properties, PVC adheres to both flat and uneven surfaces and can therefore be removed in one piece, even after a long period of gluing. In addition to good resistance to water, oil and alkalis, PVC labels can be used in a temperature range from -40° C to + 80° C. This particularly favors outdoor use, with high demands on weather, abrasion and moisture resistance. But PVC labels are also often found in the packaging industry, in product labeling and even in laboratories. |