Label width

Label width

ILX 5X: 20 … 60 mm

ILX 8X: 20 … 90 mm

ILX 10X: 20 … 112 mm

Label height

Label height

stamp on: 15 … 210 mm

blow on: 15 … 100 mm

roll on: 70 … 210 mm

Utilizable cylinder stroke

Utilizable cylinder stroke

stamp on: 170 mm

blow on: 170 mm

roll on: 200 mm

Etikettenbreite

Etikettenbreite

ILX 5X: 20 … 60 mm

ILX 8X: 20 … 90 mm

ILX 10X: 20 … 112 mm

Compressed air pressure

Compressed air pressure

Etikettenhöhe

Etikettenhöhe

Stempeln: 15 … 210 mm

Blasen: 15 … 100 mm

Anrollen: 70 … 210 mm

Product surface

Product surface

nutzbarer Zylinderhub

nutzbarer Zylinderhub

Stempeln: 170 mm

Blasen: 170 mm

Anrollen: 200 mm

Product height variable

Product height variable

stamp on: X

blow on: -

roll on: X

Product height fixed

Product height fixed

stamp on: X

blow on: X

roll on: X

Produktoberfläche

Produktoberfläche

Product fixed

Product fixed

stamp on: X

blow on: X

roll on: -

Product linear movement

Product linear movement

stamp on: -

blow on: X

roll on: X

Produkthöhe variabel

Produkthöhe variabel

Stempeln: X

Blasen: -

Anrollen: X

Produkthöhe fest

Produkthöhe fest

Stempeln: X

Blasen: X

Anrollen: X

Labelling from top

Labelling from top

stamp on: X

blow on: X

roll on: X

Produkt in Ruhe

Produkt in Ruhe

Stempeln: X

Blasen: X

Anrollen: -

Labelling from bottom

Labelling from bottom

stamp on: X

blow on: X

roll on: X

Produkt in Bewegung

Produkt in Bewegung

Stempeln: -

Blasen: X

Anrollen: X

Labelling from the side

Labelling from the side

stamp on: X

blow on: X

roll on: X

Etikettierung von oben

Etikettierung von oben

Stempeln: X

Blasen: X

Anrollen: X

Retraction depth

Retraction depth

stamp on: 25 mm

blow on: -

roll on: -

Etikettierung von unten

Etikettierung von unten

Stempeln: X

Blasen: X

Anrollen: X

Etikettierung von der Seite

Etikettierung von der Seite

Stempeln: X

Blasen: X

Anrollen: X

Compressed air control/current supply

Compressed air control/current supply

Eintauchtiefe

Eintauchtiefe

Stempeln: 25 mm

Blasen: -

Anrollen: -

Service unit

Service unit

filter regulation with manometer ans shut-off valve

Ausrichtung

Ausrichtung

rechte und linke Ausführung

Voltage supply/ current supply

Voltage supply/ current supply

Druckluft- und Vakuumüberwachung

Druckluft- und Vakuumüberwachung

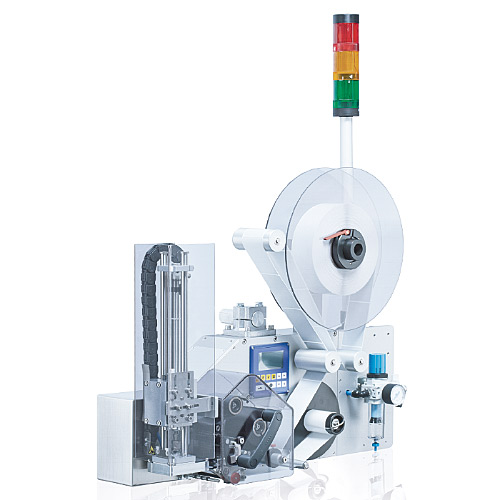

Dimensions (weight x height x depth)

Dimensions (weight x height x depth)

approx. 237 x 423 x 126 mm

Wartungseinheit

Wartungseinheit

Filter-Regler mit Manometer und Absperrventil

Spannungs-/ Stromversorgung

Spannungs-/ Stromversorgung

durch Etikettendrucksystem

Abmessungen (Breite x Höhe x Tiefe)

Abmessungen (Breite x Höhe x Tiefe)

Label width

Label width

ILX 5X: 20 … 60 mm

ILX 8X: 20 … 90 mm

ILX 10X: 20 … 112 mm

Label height

Label height

stamp on: 15 … 210 mm

blow on: 15 … 100 mm

roll on: 70 … 210 mm

Utilizable cylinder stroke

Utilizable cylinder stroke

stamp on: 270 mm

blow on: 270 mm

roll on: 300 mm

Compressed air pressure

Compressed air pressure

Product surface

Product surface

Product height variable

Product height variable

stamp on: X

blow on: -

roll on: X

Product height fixed

Product height fixed

stamp on: X

blow on: X

roll on: X

Product fixed

Product fixed

stamp on: X

blow on: X

roll on: -

Product linear movement

Product linear movement

stamp on: -

blow on: X

roll on: X

Labelling from top

Labelling from top

stamp on: X

blow on: X

roll on: X

Labelling from bottom

Labelling from bottom

stamp on: X

blow on: X

roll on: X

Labelling from the side

Labelling from the side

stamp on: X

blow on: X

roll on: X

Retraction depth

Retraction depth

stamp on: 25 mm

blow on: -

roll on: -

Compressed air control/vacuum control

Compressed air control/vacuum control

Service unit

Service unit

filter regulation with manometer and shut-off valve

Voltage supply/ current supply

Voltage supply/ current supply

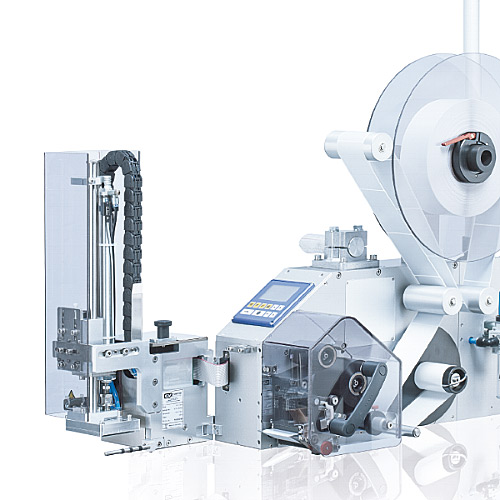

Dimensions (width x height x depth)

Dimensions (width x height x depth)

approx. 237 x 523 x 126 mm

Label width

Label width

ILX 5X: 20 … 60 mm

ILX 8X: 20 … 90 mm

ILX 10X: 20 … 112 mm

Label height

Label height

stamp on: 15 … 210 mm

blow on: 15 … 100 mm

roll on: 70 … 210 mm

Utilizable cylinder stroke

Utilizable cylinder stroke

stamp on: 370 mm

blow on: 370 mm

roll on: 400 mm

Compressed air pressure

Compressed air pressure

Product surface

Product surface

Product height variable

Product height variable

blow on: X

blow on: -

roll on: X

Product height fixed

Product height fixed

stamp on: X

blow on: X

roll on: X

Product fixed

Product fixed

stamp on: X

blow on: X

roll on: -

Product linear movement

Product linear movement

stamp on: -

blow on: X

roll on: X

Labelling from top

Labelling from top

stamp on: X

blow on: X

roll on: X

Labelling from bottom

Labelling from bottom

stamp on: X

blow on: X

roll on: X

Labelling from the side

Labelling from the side

stamp on: X

blow on: X

roll on: X

Retraction depth

Retraction depth

stamp on: 25 mm

blow on: -

roll on: -

Compressed air control/vacuum control

Compressed air control/vacuum control

Service unit

Service unit

filter regulation with manometer and shut-off valve

Voltage supply/ current supply

Voltage supply/ current supply

Dimensions (width x height x depth)

Dimensions (width x height x depth)

approx. 237 x 623 x 126 mm

Label width

Label width

ILX 5X: 20 … 60 mm

ILX 8X: 20 … 90 mm

ILX 10X: 20 … 112 mm

Label height

Label height

stamp on: 15 … 210 mm

blow on: 15 … 100 mm

roll on: 70 … 210 mm

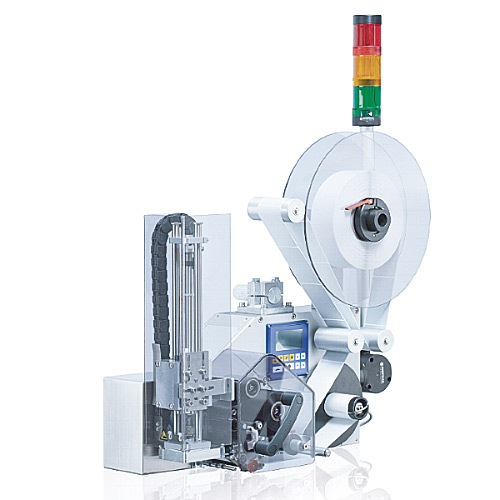

Utilizable cylinder stroke

Utilizable cylinder stroke

stamp on: 470 mm

blow on: 470 mm

roll on: 500 mm

Compressed air pressure

Compressed air pressure

Product surface

Product surface

Product height variable

Product height variable

blow on: X

blow on: -

roll on: X

Product height fixed

Product height fixed

stamp on: X

blow on: X

roll on: X

Product fixed

Product fixed

stamp on: X

blow on: X

roll on: -

Product linear movement

Product linear movement

stamp on: -

blow on: X

roll on: X

Labelling from top

Labelling from top

stamp on: X

blow on: X

roll on: X

Labelling from bottom

Labelling from bottom

stamp on: X

blow on: X

roll on: X

Labelling from the side

Labelling from the side

stamp on: X

blow on: X

roll on: X

Retraction depth

Retraction depth

stamp on: 25 mm

blow on: -

roll on: -

Compressed air control/vacuum control

Compressed air control/vacuum control

Service unit

Service unit

filter regulation with manometer and shut-off valve

Voltage supply/ current supply

Voltage supply/ current supply

Dimensions (width x height x depth)

Dimensions (width x height x depth)

approx. 237 x 723 x 126 mm