Printing

Print length

intermittent mode: max 40 mm

continuous mode: max 3000 mm

Printing

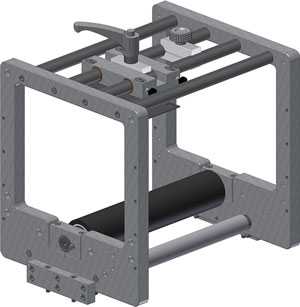

Frame passage width

Printing

Print resolution

Printing

Back speed

max 600 mm/s (intermittent mode only)

Transfer ribbon

Roll diameter

Transfer ribbon

Core diameter

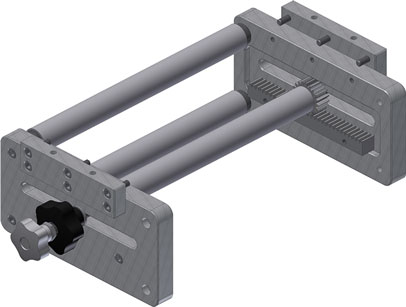

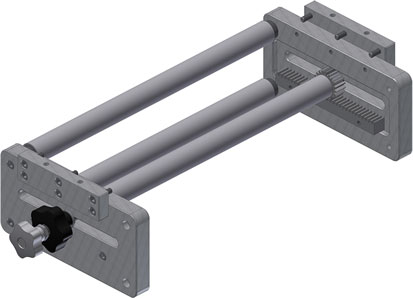

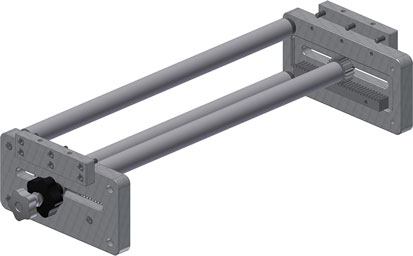

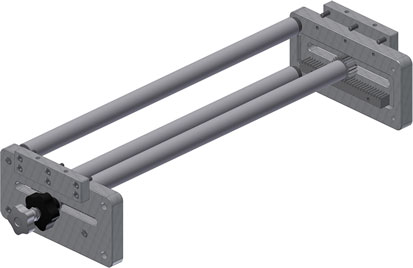

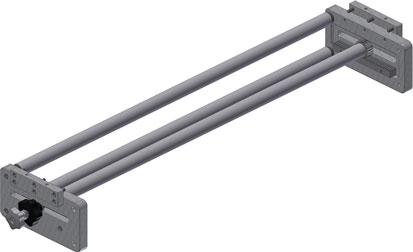

Dimensions (width x height x depth)

Print mechanics

without mounting frame: 190 x 180 x 208 mm

with mounting frame: depending on the passage width

Dimensions (width x height x depth)

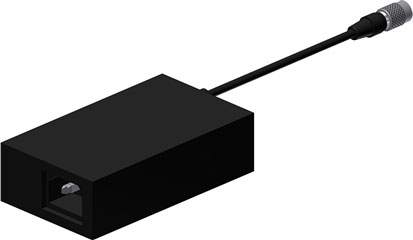

Control unit

Dimensions (width x height x depth)

Connecting cable set to print mechanics

Electronics

Slot

for Compact Flash Card type I

Electronics

Battery cache

for real-time clock (data storage when shutdown)

Electronics

Warning signal

acoustic signal when error

Interfaces

Serial

RS-232C (up to 115200 baud)

Interfaces

Ethernet

10/100 Base T, LPD, RawIP-Printing, DHCP, HTTP, FTP

Interfaces

2 x USB Master

connection for external USB keyboard and memory stick

Connection values

Pneumatic connection

Connection values

Air consumption typical*

150 ml/min

* hub 1.5 mm; 150 cycle/min; 6 bar operating pressure

Connection values

Nominal voltage

standard: 230 V AC / 50-60 Hz

option: 115 V AC / 50-60 Hz

Connection values

Nominal current

230 V AC / 1.5 A - 110 V AC / 3 A

Connection values

Fuse rating

Operation data

Operating temperature

Operation data

Relative humidity

max 80 % (non-condensing)

Operation data

Average sound power level

69 dB(A) - measuring distance 1 m

Operation panel

Keys

test print, function menu, quantity, CF card, feed, enter, 4 x cursor

Operation panel

LCD display

graphic display 132 x 64 pixel

Settings

-

date, time, shift times

11 language settings (other languages on request)

label parameters, printer parameters, interfaces, password protection

Monitoring

Stop printing if

end of ribbon, end of foil, printhead open

Monitoring

Status report

extensive status print with information about settings, e.g. print length counter, runtime counter, photocell, interface parameters, network parameters

printout of all internal fonts and all supported bar codes

Fonts

Font types

6 bitmap fonts

8 vector fonts/TrueType fonts

6 proportional fonts

other fonts on request

Fonts

Character sets

Windows 1250 up to1257, 437, 850, 852, 857

all West and East European, Latin, Cyrillic, Greek and Arabic (option) characters are supported

other character sets on request

Fonts

Bitmap fonts

size in width and height 0.8 … 5.6

zoom 2 … 9

orientation 0°, 90°, 180°, 270°

Fonts

Vector fonts/<br/>TrueType fonts

size in width and height 1 … 99 mm

variable zoom

orientation 0°, 90°, 180°, 270°

Fonts

Font attributes

depending on character font

bold, italic, inverse, vertical

Bar codes

1D bar codes

CODABAR, Code 128, Code 2/5 interleaved, Code 39, Code 39 extended, Code 93, EAN 13, EAN 8, EAN ADD ON, GS1-128, Identcode, ITF 14, Leitcode, Pharmacode, PZN Code, UPC-A, UPC-E

Bar codes

2D bar codes

Aztec Code, CODABLOCK F, DataMatrix, GS1 DataMatrix, MAXICODE, PDF 417, QR Code

Bar codes

Composite bar codes

GS1 DataBar Expanded, GS1 DataBar Limited, GS1 DataBar Omnidirectional, GS1 DataBar Stacked, GS1 DataBar Stacked Omnidirectional, GS1 DataBar Truncated

Bar codes

variable in height, module width and ratio

orientation 0°, 90°, 180°, 270°

optionally with check digit and human readable line

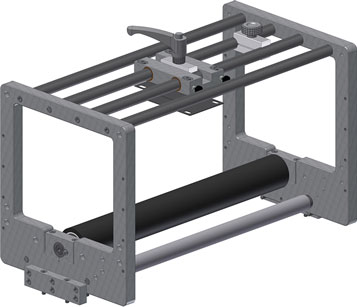

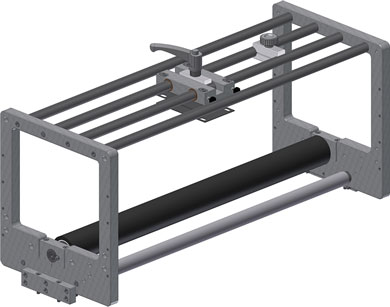

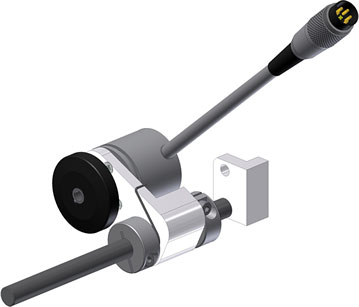

![[Translate to English:] Kabelabgang](/fileadmin/user_upload/PictureGallery/Flexicode/3carlvalentin_etikettendrucker_direktdruckwerke_flexicode_110720_135.jpg)